In a new initiative from Triscan, the Danish company with distribution throughout most of Europe once again aims at making the sourcing of a complex product easy for the wholesale / distributor level and hereby also for garages in the European free aftermarket.

The new programme includes sensors for engine and brake management for the entire European car parc, including Asian car makes, and is intended to be introduced in three steps. Today the free aftermarket for sensors is characterized by a large number of suppliers with narrow product ranges, which are either based on rather few car makes, or just a few of the sensors which are part of the car’s engine and braking control. Triscan is going to change this! Experience shows that offering a comprehensive programme to wholesalers, distributors and garages in the free aftermarket leads to increased sales and more profits.

ABS sensors, wear indicators for brake pads and oxygen sensors are introduced in the first step. "We have extended our central warehouse in Aarhus by more than 5,500 location IDs, and at the same time we have also stocked our four local stores in Denmark and Germany," says Sales and Marketing Director Steen Ray Pedersen. In the second and third step, only sensors associated with the engine control unit will be introduced.

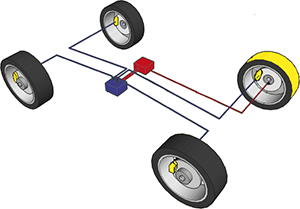

ABS sensors and wear indicators

The extension of the range of ABS sensors and wear indicators does not only complement but it also completes Triscan’s product range within the brake system programme, which also includes ABS rings. "Since its introduction just over a year ago, we have seen a strong demand for our ABS rings across Europe," says Steen Ray Pedersen and continues: "Firstly, part of the success is based on Triscan’s ability to spot unmet needs in the market for niche products. Secondly, we have launched the widest programme comprising more than 140 different ABS rings, all of which are made of extra tensile and special steel". The brake pad wear indicators, which Triscan now launches, are all of the clip-on type and should be replaced every time the brake pads are replaced.

Plug and Play

Among the leading suppliers of oxygen sensors, it is not unusual to encounter the so-called universal oxygen sensors. With this type of oxygen sensor, the original connector must be reused. This means that the oxygen sensor’s 4 or 5 conductors have to be soldered, insulated, and last but not least sealed in, so that the whole joint can resist heat, cold, moisture, salt and dirt. "This method is time consuming, encounters risk of incorrect connection of the oxygen sensor and it gets very sensitive around the joint," says Product Manager Peter Voldsgaard from Triscan and continues, "Although it requires much more references in the product range, we believe that the plug and play oxygen sensors is the best solution. This ensures the wholesaler, the workshop, and especially the car owners a seamless repair with a long service life".

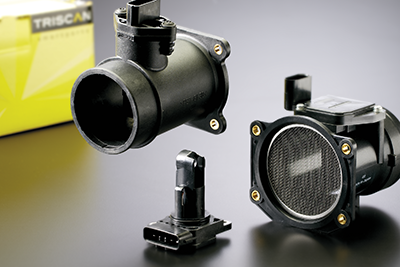

Air flow meter

The air flow meters (MAF) is one of the new sensors, which we have added into our programme. Just as Triscan’s other sensors, the programme of air flow meters are also manufactured according to the strict quality assurance standard – TS 16949 - of the automobile industry, and therefore we do only have air flow meters in OE quality in our programme. With more than 300 references we offer a programme with a large coverage. There are three types of air flow meters in the programme: MAF with warm and/or cold thread, Kármán Vortex sensors and membrane sensors.

Premium quality is a must

Unfortunately, oxygen sensors of poor quality find their way to the free aftermarket on a regular basis. Especially in the field of sensors for engine management, the consequences of poor quality are very costly, time consuming and bad for the relationship between the car owner, the garage and the wholesaler. "We have as always been very attentive to the quality and have made sure that it meets our very high standards," says Product Director Jørgen Grand from Triscan and continues, "All sensors are manufactured according to OE specifications and the automotive industry standard TS 16 949. One example is that a 100% functional test of every oxygen sensor and ABS sensor is performed as part of the manufacturing process".

Update

In continuation of the new approach two product programmes that are closely associated with the sensor programme have been updated - thermo switches and ignition coils. The programme of thermo switches now consists of more than 150 references. Within the ignition coils, there are now more than 340 references, and the programme has been specially extended by pencil / top plug coils, rail coils and block ignition coils for the most recent part of the car parc.